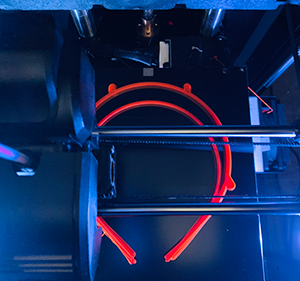

The University of Guelph is putting its many 3-D printers on campus to work to create much-needed protective medical supplies for local health and essential services providers.

With Canada facing a dwindling supply of personal protective equipment, the printers are being used to create face shields for health workers to protect them and keep them healthy while they care for those with COVID-19.

When Mairin Scannell with the John F. Wood Centre for Business and Student Enterprise at U of G’s Gordon S. Lang School of Business and Economics heard of the shortage of protective equipment, she wanted to help. She set to work using the 3-D printer in the MakerSpace studio to print out plastic frames for face shields.

Each frame takes close to three hours to make, but Scannell has been busily printing off frames one by one. She sent the first batch last week to InkSmith, a Kitchener, Ont.-based education technology company that has been collecting frames created locally. The company will outfit each frame with clear, laser-cut plastic face guards.

“These face masks will then be distributed to the essential workers in the region who have been requesting them, including pharmacists, veterinary offices and medical clinics,” Scannell said.

Scannell is also collaborating with John Philips, senior design engineer with the Interdisciplinary Design Lab (IDL) in U of G’s College of Arts, to explore making a face shield with a slightly different design. The new design uses a headband that takes only an hour to print at the Wood Centre and can be put together with a clear shield at the hospital.

“This new design will be used by front-line health care workers at Michael Garron Hospital in Toronto, which has requested help sourcing headbands, shields and other protective equipment,” Scannell said.

Scannell and Philips hope to go one step further and redesign the components so that people with smaller, portable 3-D printers can contribute by printing the frames in two pieces that will snap together.

“We are proud to be providing these donations, which will help health-care and other front-line workers continue to provide care for those in need,” said Wood Centre executive director Melanie Lang.

In U of G’s School of Engineering, senior computer engineering laboratory coordinator Matthew Saunders has been putting the lab’s 3-D printer to work to create shields as well.

“These will be going to St. Joseph’s Health Centre and other health-care facilities in the area,” said Saunders, who has also launched a Guelph Makers group on Facebook to coordinate the efforts of other community members with 3-D printers and other equipment.

In the School of Fine Art and Music, sculpture technician Paul Lovell is using two 3-D printers to create protective face shields as well.

The printers are normally used by studio art students who want to print small models of famous sculptures or try their hand at virtual sculpting.

“They’re great tools for our students but these printers were just sitting idle on campus, so now we’re putting them to use,” he said.

The frames he’s created will be sent to Shop3D, a Canadian 3-D printer distributor that’s helping to get printed equipment into the hands of essential service workers.

The 3-D printing initiatives are just one way that U of G is responding to the call of Canada’s leaders to donate much-needed medical supplies and resources.

The University recently donated 10,000 N95 masks to local hospitals as well as materials to create hand sanitizers and also plans to ship and distribute more supplies to local health authorities.