The AI revolution has come for our tomatoes.

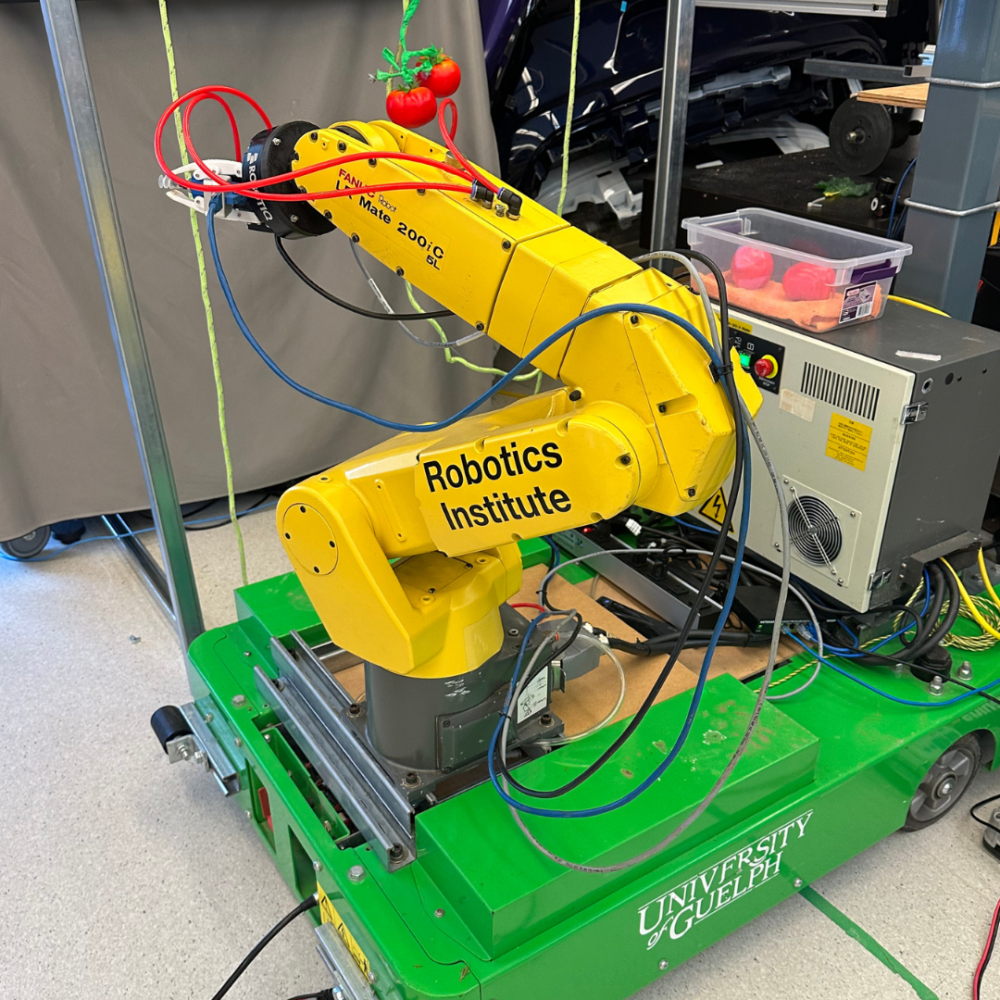

At Dr. Medhat Moussa’s laboratory in the University of Guelph’s School of Engineering, a yellow-armed robot stands on a platform facing a model tomato plant. It cranes toward the tomato when the start button is clicked.

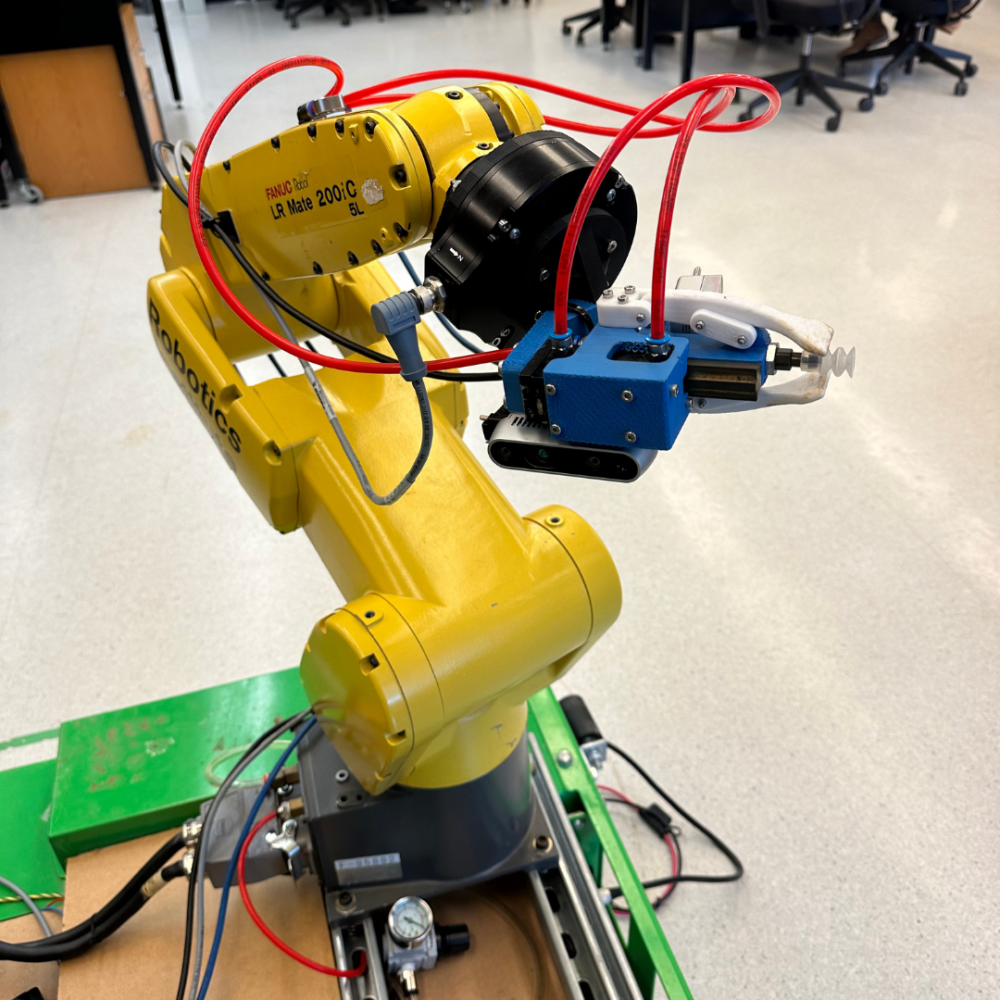

The robot examines the plant with embedded cameras, tilting its head as if “thinking” with its machine vision algorithm. It grabs the tomato with finger-like grippers and sets the product perfectly into a bin.

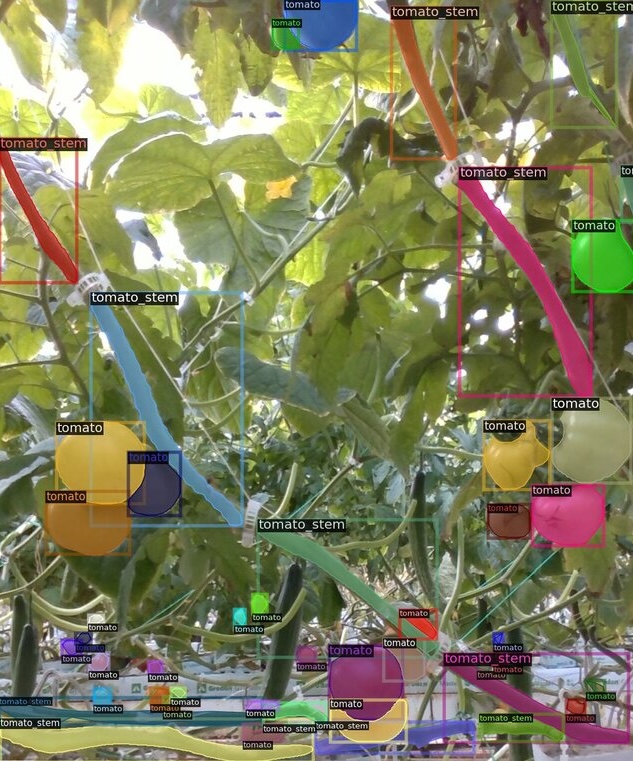

This latest iteration of Guelph Intelligent Greenhouse Automation System (GIGAS), a smart robot developed at The Robotics Institute @ Guelph, harvests tomatoes using AI-powered vision and an innovative gripping system. It uses deep learning and an image database to identify the tomato amidst environmental obstacles and to figure out how to grab it from the vine.

The U of G-developed technology was recently showcased to Ontario Premier Doug Ford and Ontario Minister of Colleges and Universities Jill Dunlop who heard how GIGAS’s automation power could soon support difficult greenhouse working conditions and agricultural labour shortages.

The need for advanced agriculture technology is critical. A recent report from the Canadian Agriculture Human Resource Council predicts that one-third of the agricultural workforce will retire by 2030, leaving more than 100,000 jobs needing to be filled.

Innovative technology, according to the report, could be a crucial solution to tackling this chronic labour shortage, and the University of Guelph is leading the charge.

U of G is leading smart robotics

“I would say U of G is ahead in smart robotics for greenhouses and harvesting,” project lead Moussa says. “We started this project in 2010. Now we’re ahead of other universities and even industry. This is a very challenging problem and you’d be hard pressed to find a robot that’s actually being sold for this application.”

Research associate Cole Tarry stands by to give a demonstration, having worked on this project for several years.

“No other research lab that we know of is working on robotics for beefsteak tomatoes, which are generally the most difficult to work with,” Tarry adds. “The robots closest to commercialization work with cherry tomatoes or cucumbers.”

There are other applications to the technology being developed in the lab. It could be trained to harvest other vegetables such as peppers and cucumbers. Those are the other two major crops in Leamington, Ont., where this project was first inspired by growers who urged the development of automated solutions.

Other iterations of GIGAS focused on the detection of plant diseases. The technology learns from image datasets that include healthy and diseased leaf shapes to identify a disease and to quantify how severe it is. This could pick up on early signs of diseases, a critical skill in an environment like tomato greenhouses.

Catching early signs of disease could reduce the cost of treatment and the amount of chemicals used. It could ultimately save other produce from diseases that can spread and destroy entire crops.

GIGAS could also be used in the manufacturing industry one day, especially as two local Guelph automotive plants have used the technology before. In these applications, the GIGAS AI engine helps identify various hard-to-see manufacturing defects or enables robotics to pick and place solutions for fragile and irregular parts.

Supporting labour shortages and efficiencies is always top of mind for the team. Moussa adds that they’re always seeking projects that add economic value.

Honing AI vision through long-term testing

Moussa and his team hope to bring GIGAS out to greenhouses for long-term field testing next. There, they can collect critical data points needed to strengthen the robot’s AI learning and validate the value proposition, bringing it a step closer to commercialization.

Testing will help them find the sweet spot where GIGAS becomes fast and cheap enough to compete with rising labour costs.

“Humans take four to five seconds to harvest a tomato, whereas GIGAS currently takes 15 seconds,” research associate Cole Tarry says. “We’re hoping to cut that down to eight seconds. Assuming robots can work longer hours and you could have multiple robots, that could be game-changing.”

The team did not start with machine learning when developing GIGAS’s vision system. Now, deep learning has sped up the development of the vision algorithm that correctly identifies tomatoes at varying stages of ripeness and in even the most cluttered environments. They no longer have to manually tinker with calculations “pixel by pixel.”

Years of valuable learning

Over 10 years, more than 20 students have worked on GIGAS. Recently graduated master’s students have just honed its innovative gripping system.

“There have been many students who have gone through this project and are now working in industry,” Moussa says. “Some of them work directly on products like this. Our PhD student who worked on disease detection is now an R&D director for his company. It has been valuable years of learning.”

GIGAS has been supported by several funding agencies, including Ontario Centres of Excellence (OCE), Agriculture and Agri-food Canada, and the National Sciences and Engineering Research Council (NSERC) and the Ontario Agri-Food Innovation Alliance, a collaboration between the Government of Ontario and U of G.

Contact:

Media Relations

media@uoguelph.ca